New Alloy Won't Crack at Extreme Temperatures

Science Highlight

June 6, 2024

By Elizabeth Ball

Contact: cscomms@lbl.gov

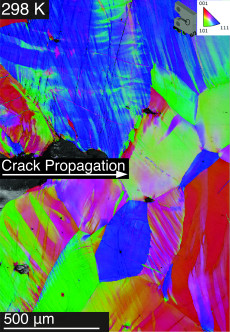

One of a series of material samples shows the behavior of the alloy when stressed at a temperature of 298 K.

Science Breakthrough

With the help of NERSC systems, researchers have uncovered a metal alloy that won’t crack at extreme temperatures due to kinking, or bending, of the crystals in the alloy at the atomic level. The team, led by Robert Ritchie at Lawrence Berkeley National Laboratory (Berkeley Lab) and UC Berkeley, discovered the alloy’s properties and then figured out how they arise from interactions in the atomic structure. Their work is described in a study that was published April 11, 2024 in Science.

Science Background

The alloy composed of niobium, tantalum, titanium, and hafnium displayed impressive strength and toughness at both extremely hot and extremely cold temperatures, a combination of properties that previously seemed near-impossible. In this context, strength is defined as how much force a material can withstand before it is permanently deformed from its original shape, and toughness is its resistance to fracturing (cracking). The alloy’s resilience to bending and fracture across a wide range of conditions could open the door for a novel class of materials for next-generation engines that can operate at higher efficiencies.

Science Breakdown

In addition to experimental observation of the material at Berkeley Lab’s Molecular Foundry, the team used the Vienna Ab Initio Simulation Package (VASP) on the GPU partition on Perlmutter to calculate generalized stacking fault (GSF) energy profiles of pure niobium and the discovered alloy (Nb45Ta25Ti15Hf15). The GSF calculations provide insight into how the alloyed material behaved when stressed, compared with the behavior of pure niobium. They found that alloying effects not only lowered the unstable energy of the material, but also induced isotropy between different families of slip planes, both of which correlate with an improved ability to bend. Perlmutter GPU enabled this work because the study of high-entropy alloys requires large simulation cells to properly model the effects of compositional disorder, and the compute power of the GPUs allows for large-scale first-principles calculations that can make clear the underlying physics controlling the deformation mechanisms observed in the material during experiments.

Research Lead

David H. Cook, Punit Kumar

Co-authors

M. Payne, C. Belcher, P. Borges, W. Wang, F. Walsh, Z. Li, A. Devaraj, M. Zhang, M. Asta, A. Minor, E. Lavernia, D. Apelian, R. Ritchie

Publication

David H. Cook et al. , Kink bands promote exceptional fracture resistance in a NbTaTiHf refractory medium-entropy alloy. Science 384,178-184 (2024). DOI:10.1126/science.adn2428

Funding

DOE Office of Science, Office of Basic Energy Sciences

User Facilities

NERSC, Molecular Foundry

About NERSC and Berkeley Lab

The National Energy Research Scientific Computing Center (NERSC) is a U.S. Department of Energy Office of Science User Facility that serves as the primary high performance computing center for scientific research sponsored by the Office of Science. Located at Lawrence Berkeley National Laboratory, NERSC serves almost 10,000 scientists at national laboratories and universities researching a wide range of problems in climate, fusion energy, materials science, physics, chemistry, computational biology, and other disciplines. Berkeley Lab is a DOE national laboratory located in Berkeley, California. It conducts unclassified scientific research and is managed by the University of California for the U.S. Department of Energy. »Learn more about computing sciences at Berkeley Lab.