Advanced Computational Methods for Turbulence and Combustion

Key Challenges: Development and application of advanced algorithms that

exploit known separations in scale and run several orders of magnitude more efficiently than traditional simulation approaches for a variety of application areas, including non-reacting, turbulent flow and combustion in laboratory-scale and small-scale flames. Theoretical studies are unable to directly address the complexity of realistic flames; laboratory data are difficult to interpret and are often limited in detail. Simulation is intended to augment laboratory diagnostics but modeling realistic combustion devices is an immense undertaking because of the time and space scales, involved, because of turbulence, and because the combustion process may involve hundreds of species and thousands of chemical reactions.

Why it Matters: Fundamental understanding of flames will enable the design of near-zero-emissions combustion technologies that use a variety of premixed lean fuels for clean, efficient combustion devices such as low-swirl burners. Over 80% of energy consumed in the U.S. occurs via the burning of fossil fuels in transportation systems, heat, and stationary power generation systems. This is why research into more efficient fuel and engine technologies offers enormous potential for savings as well as for pollutant reduction.

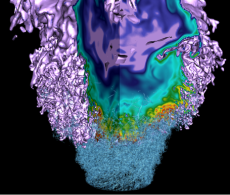

Accomplishments: Statistically stationary flames have been computed for a variety of flow rates and fuel mixtures and have been validated with mean and instantaneous flow and flame measurements. This has allowed characterization of flame shape, flow, local burning, and emissions across a range of flow and fueling scenarios at a spectacular level of detail (see image). The simulated chemical details are experimentally inaccessible, but are nevertheless critical for evaluation of burner scenarios. Most importantly, modeling flames at laboratory length and time scales with detailed chemistry and transport is orders of magnitude beyond the reach of traditional reacting flow simulation approaches.

The method has been successfully applied to combustion simulation of a low-swirl burner. Low swirl burners, discovered at LBNL in 1991, are being developed for fuel-flexible, near-zero emission gas burners and turbines that can be used in a wide variety of residential and industrial applications – everything from ovens and clothes dryers to HVAC systems and power generators.

Investigators: Marcus Day, Andy Aspden, Xinfeng Gao, John Bell (LBNL)

More Information: See Journal of Fluid Mechanics, 635:137-169, 2009, and the CCSE web site .